Innovation/Design

Engineering

Manufacturing

Our state-of-the-art Florida manufacturing facility features the most modern assembly equipment available, including:

- 5 Axis computerized CNC machines

- Shear and metal break

- Advanced mixing silicone pumps

- Custom designed glazing station

Continental Glass Systems also provides green building training to employees and encourages employees to attain LEED Professional accreditation. If your company is seeking LEED certification for a project, CGS can help.

Our product lines include:

- Window Wall

- Sliding Glass Door

- Ribbon Windows

- Casement Windows

- Curtain Wall

- Swing Door (ADA)

- Horizontal Rolling Windows

- Project-Out Windows

- Single Hung Windows

- ACP (Aluminum Composite Panels)

- Railing System

- Skylights

- Ornamental Metals

- Steel Structures

- Louvers and Grills

Installation

Being a one-stop shop means that Continental Glass also delivers and installs your product. We handle all site logistics and scheduling. We adhere to all safety standards and are OSHA trained and certified using OSHA approved field safety equipment and processes.

We use advanced installation equipment including 3-axis glass suction cups, hydraulic manipulators, lifts of all kinds and swing stages. Continental also has all tools and equipment needed for installing fire-rated interior and exterior systems as well as various interior systems such as shower doors, partitions, decorative glass, spandrel, and railings.

Fenestration Testing

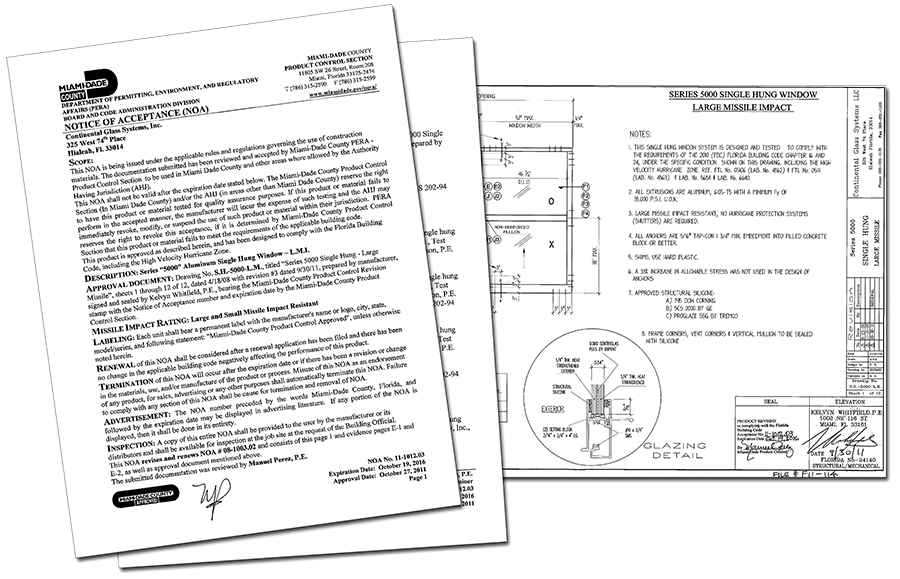

NOA/FL Compliant